Ulti-Mate Connector, Inc. has been producing world-class Micro-miniature connectors and interconnect solutions since 1977. Their expertise in the design and production of customized solutions to the most demanding customer requirements has made Ulti-Mate a valued supplier to the OEM Marketplace.

Ulti-Mate specializes in serving the unique interconnect needs of military, space, aviation, medical, and geophysical exploration marketplaces. Innovation and quality has placed Ulti-Mate connectors in many of our country’s most advanced missile systems, manned space and satellite vehicles, and guidance and navigation systems. Ulti-Mate has a long history of meeting the rigorous specifications of invasive and noninvasive medical imaging, patient monitoring and measured drug delivery markets.

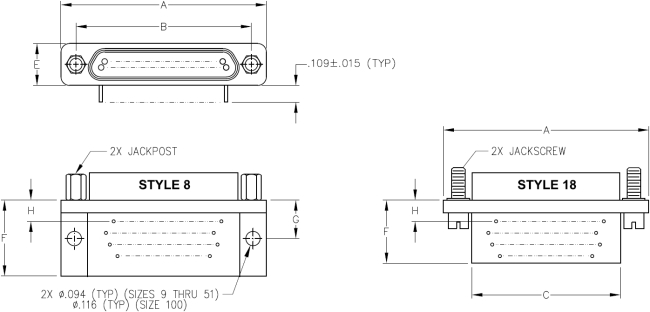

| Size | A Max. | B Nom. | C Max. | E Max./ A & P. | E Max./ M & B | |||

| 9 | .785 (19.94) | .565 (14.35) | .400 (10.16) | .215 (5.46) | .308 (7.82) | |||

| 15 | .935 (23.75) | .715 (18.16) | .550 (13.97) | .215 (5.46) | .308 (7.82) | |||

| 21 | 1.085 (27.56) | .865 (21.97) | .700 (17.78) | .215 (5.46) | .308 (7.82) | |||

| 25 | 1.185 (30.10) | .965 (24.51) | .800 (20.32) | .215 (5.46) | .308 (7.82) | |||

| 31 | 1.335 (33.91) | 1.115 (28.32) | .950 (24.13) | .215 (5.46) | .308 (7.82) | |||

| 37 | 1.485 (37.72) | 1.265 (32.13) | 1.100 (27.94) | .215 (5.46) | .308 (7.82) | |||

| 51-3 | 1.435 (36.45) | 1.215 (30.86) | 1.045 (26.54) | .255 (6.48) | .351 (8.92) | |||

| 100 | 2.165 (54.99) | 1.800 (45.72) | 1.550 (39.37) | N/A | .394 (10.01) | |||

| Size | F Max. | G Max. | H Max. | |||||

| 9 | .410 (10.41) | .250 (6.35) | .138 (3.51) | |||||

| 15 | .410 (10.41) | .250 (6.35) | .138 (3.51) | |||||

| 21 | .410 (10.41) | .250 (6.35) | .138 (3.51) | |||||

| 25 | .410 (10.41) | .250 (6.35) | .138 (3.51) | |||||

| 31 | .410 (10.41) | .250 (6.35) | .138 (3.51) | |||||

| 37 | .410 (10.41) | .250 (6.35) | .138 (3.51) | |||||

| 51-3 | .500 (12.70) | .295 (7.49) | .145 (3.68) | |||||

| 100 | .615 (15.62) | .350 (8.89) | .163 (4.14) | |||||

Sales Drawings

![]() Male Style 8 Circuits Size(9-37) PDF file

Male Style 8 Circuits Size(9-37) PDF file

![]() Male Style 8 Circuits Size 51 PDF file

Male Style 8 Circuits Size 51 PDF file

![]() Male Style 8 Circuits Size 100 PDF file

Male Style 8 Circuits Size 100 PDF file

![]() Female Style 8 Circuits Size(9-37) PDF file

Female Style 8 Circuits Size(9-37) PDF file

![]() Female Style 8 Circuits Size 51 PDF file

Female Style 8 Circuits Size 51 PDF file

![]() Female Style 8 Circuits Size 100 PDF file

Female Style 8 Circuits Size 100 PDF file

![]() Male Style 18 Circuits Size(9-37) PDF file

Male Style 18 Circuits Size(9-37) PDF file

![]() Male Style 18 Circuits Size 51 PDF file

Male Style 18 Circuits Size 51 PDF file

![]() Male Style 18 Circuits Size 100 PDF file

Male Style 18 Circuits Size 100 PDF file

![]() Female Style 18 Circuits Size(9-37) PDF file

Female Style 18 Circuits Size(9-37) PDF file

![]() Female Style 18 Circuits Size 51 PDF file

Female Style 18 Circuits Size 51 PDF file

![]() Female Style 18 Circuits Size 100 PDF file

Female Style 18 Circuits Size 100 PDF file

| 3D Models* | ||||||||

| Style 8 | Style 18 | |||||||

| Size | Male | Female | Male | Female | ||||

| 9 | 836111817.STP | 836211817.STP | 836111012.STP | 836211012.STP | ||||

| 15 | 836121817.STP | 836221817.STP | 836121012.STP | 836221012.STP | ||||

| 21 | 836131817.STP | 836231817.STP | 836131012.STP | 836231012.STP | ||||

| 25 | 836141817.STP | 836241817.STP | 836141012.STP | 836241012.STP | ||||

| 31 | 836151817.STP | 836251817.STP | 836151012.STP | 836251012.STP | ||||

| 37 | 836161817.STP | 836261817.STP | 836161012.STP | 836261012.STP | ||||

| 51-3 | 836171817.STP | 836271817.STP | 836171012.STP | 836271012.STP | ||||

| 100 | 836181817.STP | 836281817.STP | 836181012.STP | 836281012.STP | ||||

| PCB Layouts | ||||||||

| Size | Male | Female | ||||||

| 9 | 836111817PCB.DXF | 836211817PCB.DXF | ||||||

| 15 | 836121817PCB.DXF | 836221817PCB.DXF | ||||||

| 21 | 836131817PCB.DXF | 836231817PCB.DXF | ||||||

| 25 | 836141817PCB.DXF | 836241817PCB.DXF | ||||||

| 31 | 836151817PCB.DXF | 836251817PCB.DXF | ||||||

| 37 | 836161817PCB.DXF | 836261817PCB.DXF | ||||||

| 51-3 | 836171817PCB.DXF | 836271817PCB.DXF | ||||||

| 100 | 836181817PCB.DXF | 836281817PCB.DXF | ||||||

*3D Models for Style 8 is standard profile with jackposts. 3D models for Style 18 is standard profile with jackscrews. Consult factory for other configurations

| Contact Resistance | 8 mO Maximum @ 2.5 A |

|---|---|

| Current Rating | 3.0 A Maximum |

| Dielectric Withstanding Voltage | 900 VAC at sea level, 300 VAC @ 70,000 ft. Solder cups and shielded cable same as MIL-DTL-83513; 600 VAC at sea level 150VAC @ 70,000 ft. |

| Insulation Resistance | 5,000 MO Minimum |

6 oz. max per MIL-DTL-83513 (contact average is 3 oz.); Separation force is 5.0 oz. minimum.

Mate = 10 oz. X number of contacts maximum. Unmate = 10.5 oz. X number of contacts minimum.

| Vibration | No damage or interruption detected (one microsecond sensitivity) when subjected to Method 2005, Test Condition IV of MIL-STD-1344. |

|---|---|

| Shock | No damage or interruption detected (one microsecond sensitivity) when subjected to Test Condition E. Method 2004 of MIL-STD-1344. |

| Durability | No mechanical defects after 500 matings; Test criteria are mating force, contact resistance, contact engagement, and separation forces. |

| Salt Spray | No exposure of base metal due to corrosion; no loss of performance as in durability above. |

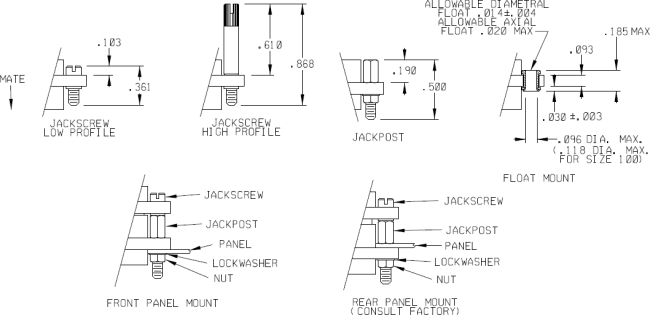

| Description | Mil Spec | UMI | A Max. | B Max. |

| Jackscrew Lo Allen | M83513/05-02 | 83041xxxx | .361 (9.17) | .103 (2.62) |

| Jackscrew Hi Allen | M83513/05-03 | 83041xxxx | .868 (22.05) | .610 (15.49) |

| Jackscrew Lo Slot | M83513/05-05 | 83041xxxx | .361 (9.17) | .103 (2.62) |

| Jackscrew Hi Slot | M83513/05-06 | 83041xxxx | .868 (22.05) | .610 (15.49) |

| Jackpost | M83513/05-07 | 83041xxxx | .500 (12.70) | .190 (4.83) |

| Jackscrew Lo Allen | M83513/05-12 | 83041xxxx | .390 (9.91) | .103 (2.62) |

| Jackscrew Hi Allen | M83513/05-13 | 83041xxxx | .902 (22.91) | .610 (15.49) |

| Jackscrew Lo Slot | M83513/05-15 | 83041xxxx | .390 (9.91) | .103 (2.62) |

| Jackscrew Hi Slot | M83513/05-16 | 83041xxxx | .902 (22.91) | .610 (15.49) |

| Jackpost | M83513/05-17 | 83041xxxx | .500 (12.70) | .185 (4.70) |

| Description | Thread | Used on Sizes | 3D Models |

| Jackscrew Lo Allen | 2-56 UNC-2A | M83513/05-02.STP | |

| Jackscrew Hi Allen | 2-56 UNC-2A | 9 | M83513/05-03.STP |

| Jackscrew Lo Slot | 2-56 UNC-2A | through | M83513/05-05.STP |

| Jackscrew Hi Slot | 2-56 UNC-2A | 51 | M83513/05-06.STP |

| Jackpost | 2-56 UNC-2B | M83513/05-07.STP | |

| Jackscrew Lo Allen | 4-40 UNC-2A | M83513/05-12.STP | |

| Jackscrew Hi Allen | 4-40 UNC-2A | M83513/05-13.STP | |

| Jackscrew Lo Slot | 4-40 UNC-2A | 100 | M83513/05-15.STP |

| Jackscrew Hi Slot | 4-40 UNC-2A | M83513/05-16.STP | |

| Jackpost | 4-40 UNC-2B | M83513/05-17.STP | |

| Pin Contacts | Beryllium Copper (C17200) per ASTM B194. |

|---|---|

| Socket Contacts | Copper alloy (C21000) per ASTM B36 or leaded commercial bronze (C314000) per ASTM B140. |

| Contact Plating | Gold plated per MIL-DTL-45204D. 50 microinches min. is the standard thickness. |

| Metal Shells | Aluminum alloy per SAE-AMS-QQ-A-200/8, type 6061-T6. Finish is cadmium per SAE-AMS-QQ-P-416, TYPE II, CLASS 3, with suitable underplate with yellow chromate, this plating is not RoHS compliant. Or Finish Electroless Nickel plate per SAE AMS2404, class 3 or 4, .0005 minimum thickness. |

| Insulator Material | Preferred material is Polyphenylene sulfide (PPS) per MIL-M-24519 or ASTM D5927 GST 40F. Color Black. |

| LCP | Liquid Crystal Polymer-Vectra 130 (optional). |

| Interfacial Seals | Fluorosilicone elastomer per MIL-R-25988. Standard on “M” Series socket face. |

| Hardware | Stainless Steel, passivated. |

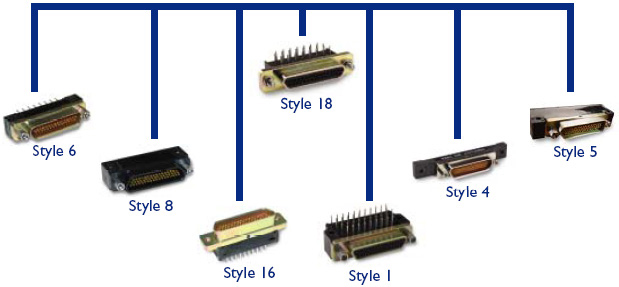

Click image to view larger image view

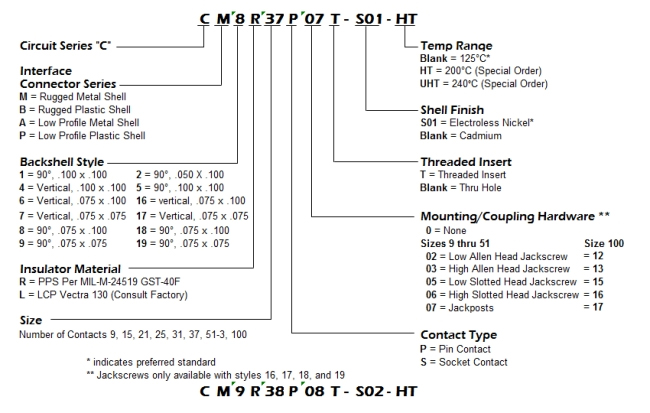

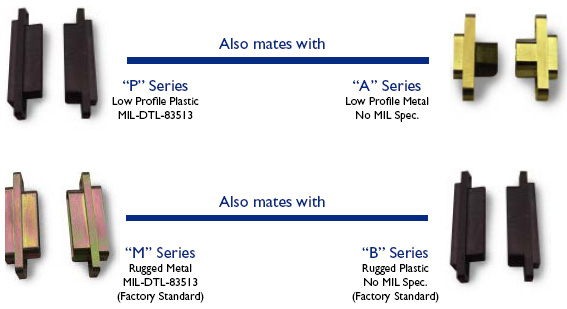

Select the type of rectangular connector you require. Note the “P” series of MIL-DTL-83513 is not designed to mate with the MIL-DTL-83513 “M” series. The “M” series mates with its dimensional plastic version “B”. The “A” series mates with its dimensional plastic version “P”.

A, P, M, and B Series 50 mil Rectangular Connectors, P and M series are in accordance with MIL-DTL-83513

|

|||||||||||||||

|

|||||||||||||||